OEM customizing anodizing aluminum sheet metal electronics enclosure

Review

Description

Product description

Item | OEM customizing anodizing aluminum sheet metal electronics enclosure |

Inspection | 1,Check the material before the production |

2,Have the random inspection during the production | |

3,Make the 100% inspection on critical dimension before the shippment. | |

Finishing | Accept customer request |

Company introduction | 1)Direct and professional manufacturer have 10 years experience in metal stamping parts. |

2)More than 40 skilled workers. | |

3)More than 5 RD engineers. They are specialized in sheet metal mould design. | |

4)OEM and ODM service is welcome |

Sheet metal fabrication

People choose sheet metal because of its amazing characteristics. For one, it’s very affordable. This is one of the most attractive benefits. It is also a pretty straight forward process of cutting, forming, and finishing the product. It just requires some practice and expertise to master the sheet metal skills. If you look into using something like plastic on the other hand, the process takes much longer which ultimately costs more money and effects your company’s bottom line.

The next advantage of sheet metal is its flexibility. Since this material is flexible, it allows you to have more options. These options come into play when implementing both simple and intricate designs into your work.

Another great benefit of working with sheet metal is the fact that it is very durable. It can stand up against numerous harsh conditions that may be present in your operations. This may include things such as high temperatures and inclement weather. The durability also allows for a long life span. That means you won’t have to replace the material as often which again saves you money and time in the long run.

Product detail

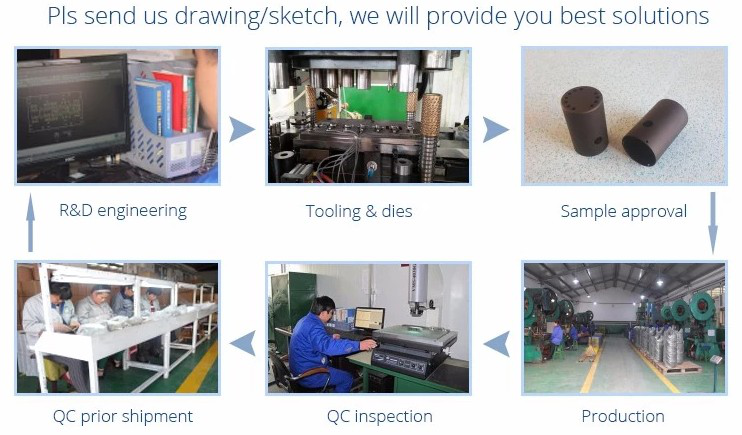

Processing

Packing & Shipping