ISO9001:2008 CNC Aluminum Alloy ADC12 Die Casting

Review

Description

Feature:

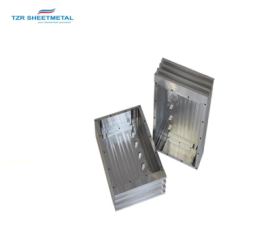

● Complex shapes with high dimensional accuracy and stability with thin walls than other mass production processes, can be used in almost any industry.

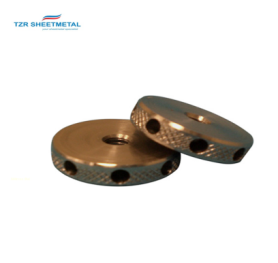

● Aluminum Die Cast parts can be manufactured with smooth or textured surfaces

● Creates lighter parts—with more surface finishing options than other die cast alloys. Easily anodized, painted or powder coated with minimal surface preparation.

● Economical process offering a wide range of sizes and shapes.

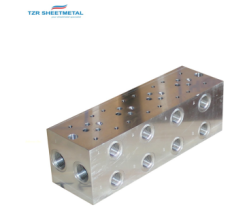

● CNC Machining can be used to further refine the design, if needed.

● Aluminum Die Cast parts are strong and have a long life span.Aluminum can withstand the highest operating temperatures of all the die cast alloys.

Application:

Aluminum die casting is used frequently in the automotive industry, as a durable, lightweight alternative to steel and iron. Aluminum die castings are used in tractor arm accessories, automobile parts, motorcycle parts, motor housings, oil pump parts, transmission machinery housings and other aluminum die-casting housings, aluminum die-casting covers, and other decorative accessories.

Technical specification:

10 HASS CNC lathes and machine cernter,4 Janpan Mitsubshi Wire cut Electrical Discharge Machining ,6 tsugami CNC automatic sliter,10 WEDM-HS machines, 12 auto precision grinding machines,6 auto milling machine, 4 mirror spark machines;