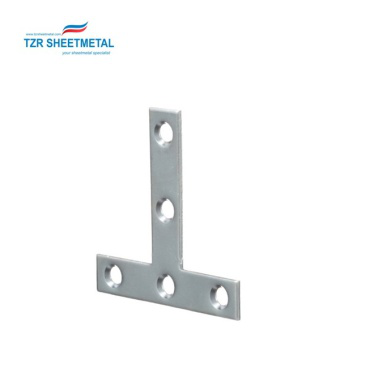

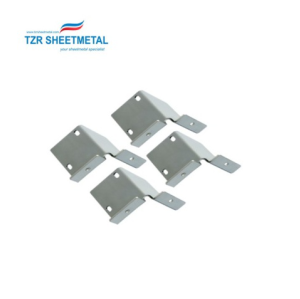

China Manufacturer Custom Made Precision Stainless Steel Sheet Metal Stamping Parts

Review

Description

Feature:

Availble Material

Aluminum: Al6061 Al6063 Al7075 Al5052 etc.

Stainless steel:SS304 SS303 SS316 SS201 etc.

Brass: C36000(C26800), C37700(HPb59), C38500(HPb58),C27200(CuZn37), C28000(CuZn40) Etc

Bronze: C5100 C52100 C54400 etc.

Iron:1213 12L14 1215 etc.

Plastic: POM ,Acetal,ABS,PTFE,etc.

Processin:stamping,deepstamping,bending,punching,threading,welding,tapping,riveting.

Finish:lating, Polish, Heat Treatment, Nickel, Zinc, Tin, Silver, Chrome Plating Etc

Tolerance:0.01mm or base on your design

Application:chinery,Automotive,Medical,Motorcyles,Telecommunication,Eletronic,Furniture,etc

File format:Solid Works,Pro/Engineer, AutoCAD(DXF,DWG), PDF,TIF etc.

Introduction:

A stamping die is a special, one-of-a-kind precision tool that cuts and forms sheet metal into a desired shape or profile. The die's cutting and forming sections typically are made from special types of hardenable steel called tool steel. Dies also can contain cutting and forming sections made from carbide or various other hard, wear-resistant materials.

Stamping is a cold-forming operation, which means that no heat is introduced into the die or the sheet material intentionally. However, because heat is generated from friction during the cutting and forming process, stamped parts often exit the dies very hot.

Package:Cartons&pallets or according to customer's requirement

Sheet metal stamping parts is the metal parts made by metal stamping. Most of our sheet metal parts are made of sheet metal. Sheet Metal Spare Parts are available in different specifications and can also be customized as per clients requirements.

Application:

The industries that employ metal stamping companies include (but are not limited to):

· Automotive

· Industrial Machinery

· Consumer Electronics

· Aerospace

· Electrical

· Telecommunication

Advantage:

1. PRECISION

If your product needs to be cut with high accuracy, a stamping company will have the tools and processes in place to do so. Cutting a shape with such precision can be a large expense and it can be tempting to lower costs by lacking in this area of production. A stamping company allows for a higher quality product at a lesser price.

2. CONSISTENCY

Some businesses would tell you that consistent precision is only guaranteed by cutting pieces one-by-one, but most top metal companies agree that this isn’t true.

Consistency in mass production can be achieved by carefully controlling the entire process, starting with precise, computer-aided design (CAD), proper tooling, professionally operated metal stamping machines, as well as quality control to inspect each piece or part and to ensure uniformity in products.

3. MASS PRODUCTION

This one speaks for itself. Need a large quantity of quality products? Hire a company the machinery and tools to manage your project in a quick and efficient manner.

4. WORKSPACE

If you outsource your stamping to a company outside of your own, then there is no need to allocate time and space in your own place of business to make those products.

Plus, it allows you to focus on the other aspects of your business and not get bogged down with the intricacies of production.