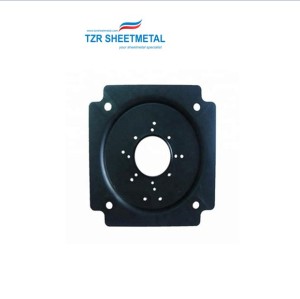

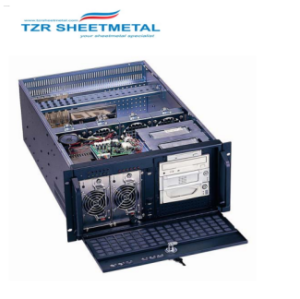

OEM Custom aluminum powder coating black sheet metal box enclosure for electrical parts

- Model

- OEM

Item specifics

- Material

- Copper, stainless steel, Aluminium ,brass,galvaniz

- Process

- cutting material, punch/stamp, bending,welding,etching,laser cutting,CNC,wire-cut

- Surface treatment

- powder coating,sand blast/ anodize/chrome / zinc /nickel plating, polished,printing,silk screen or as your special requirement.

- Equipment

- laser cutting machine, welding machine, bore machine,stamping machine, punching machine, bending machine.CNC

- Experience

- 6 years

- certification

- ISO 900012008

- sample lead time

- 6 days

- packing

- Carton,Wooden box

Review

Description

Introduction

Outdoor Sheet Metal Enclosures

All sheet metal enclosures for outdoor applications that meet NEMA standards will protect maintenance

staff and other employees from access to hazardous parts inside the part, as well as from rain, snow and sleet. The other protections vary based on type:

NEMA Type 3 Variants: The type 3 protects against dust and other fibrous materials. The 3R does not, but can be ventilated for applications where heat is an issue. The 3S is used in applications where icing or sleet can occur. Adding an X to the designation, such as 3SX, means that any of these enclosures also affords protection against corrosion from acid or basic solutions.

Application

The product is well manufactured with latest technologies and CNC machines in order to achieve quality products with high accuracy level. We manufacture the product using high grade raw material like steel, iron and many more quality material. We provide a safe packaging to the product, so that during transit product quality is maintained. Further, the product is delivered at industrial leading prices.

The uses of sheet metal enclosures

Sheet metal enclosures is use to resist corrosion and provide electrical conductivity. The product is widely used for various industrial purposes

Features

Sturdy construction

Corrosion resistance

Precision made

High strength and longer shelf life

These enclosures are epoxy coated to ensure good quality

Advantages

Can form complex shapes

Many material options

High production rate

Low labor cost

Short lead time possible