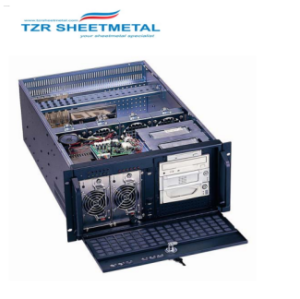

Our custom aluminum cases are designed for durable, lightweight, and stylish transport. Custom

solutions can be engineered for every need — from a light-duty presentation case to a rugged metal

shipping case intended for industrial and government applications. We have built our reputation on

delivering innovative, well engineered solutions to our customers.

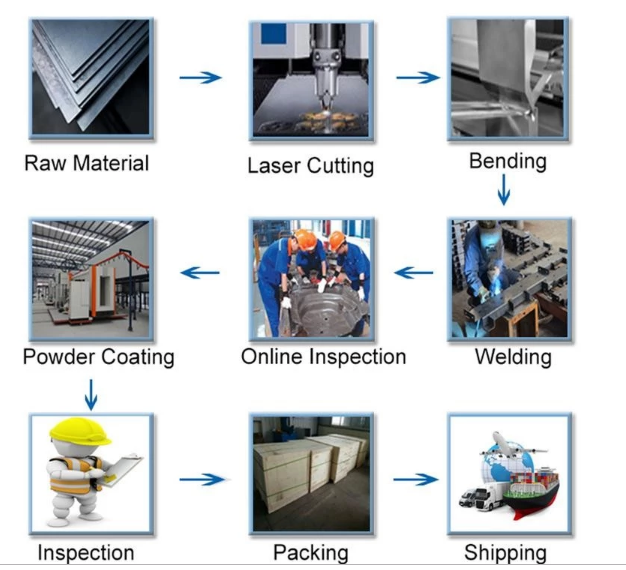

Due to the breadth of industries and applications that the OEM supports, Schaffer manufactures

enclosures in a wide range of configurations. In any configuration, an enclosure requires vertically-

integrated fabrication that provides a range of sheet metal processing options. Depending on the most

efficient, cost effective solution for a given enclosure, the operations include: laser cutting, punching,

forming, counter-sinking, tapping, hardware insertion, metal finishing, silk screening and powder

coating.

In response to the high rate of custom engineering and product development the OEM offers to

customers, Schaffer is set up and equipped to fabricate the high-quality enclosures in low-volume

quantities and on precisely timed production schedules. Receiving custom-order enclosures on-time

from Schaffer, with no quality issues, is critical in keeping the customer's assembly operations and

customer deliveries on schedule.

Materials:Carton steel/stainless steel/aluminum/galv sheet

Surface: Power coating,zinc plated,Polishing, Plating, Brush, Skill-screen etc.

Packing: Wooden frame,plastic cover MOQ: 5 unit Delivery: within 20 working days.

Service: OEM. sheet metal box fabrication

Material Aluminum: AL6061, Al6063, AL6082, AL7075, AL5052, AL2024

Stainless steel: SS201, SS301, SS303, SS304, SS316, SS430 etc

Steel: mild steel/ carbon steel including 1010, 1020, 1045, 1050, Q690 etc Brass: HPb63.