sheet metal laser cutting CNC machine Welding fabrication machine parts

Review

Description

Product description

Name | sheet metal laser cutting CNC machine Welding fabrication machine parts |

Material |

|

Finishing | Anodizing, Polishing, Zinc Plating, Nickel Plating, Chrome Plating, Powder Coating, E-coating, Anodizing, blacken etc. |

Tolerence |

|

Tolerence Of Bending:+/-0.1mm | |

Surface Roughness: Ra 3.2 | |

Accuracy Of Welding:+/-0.2mm | |

Application | Equipment/Telecommunication/Vehicle/Furniture/Autoparts |

Drawing | JPEG, PDF, CAD, IGS Accepted |

1. Durability

Sheet metals are capable of withstanding heavy pressure without collapsing. Their durability extends to the elements as well, as the metals are resistant to corrosion, moisture, and sun. Sheet metal therefore lends itself to projects in all types of environments.

2. Malleability

Despite the metals’ supreme durability, they are highly malleable and can be molded into practically any shape. The metals are ideal products for architects and building designers because there is virtually no limit to design possibilities.

3. Lightweight

Sheet metal fabrication results in incredibly lightweight products offering fantastic portability. The lightweight nature also makes it easy for workers and technicians to hold and carry the metals without strain.

4. Easy Modifications

Modifications are never an issue with sheet metal-fabricated structures and products. They make it easy to expand on assorted buildings, including vertical expansions not available with other construction materials.

5. Aesthetically Pleasing

Structures and products made with sheet metal are extremely pleasing to the eye. The result is a seamless look that is as sophisticated as it is modern. Not only can the metals be manipulated in dozens of ways, they can also be painted to increase their aesthetic appeal.

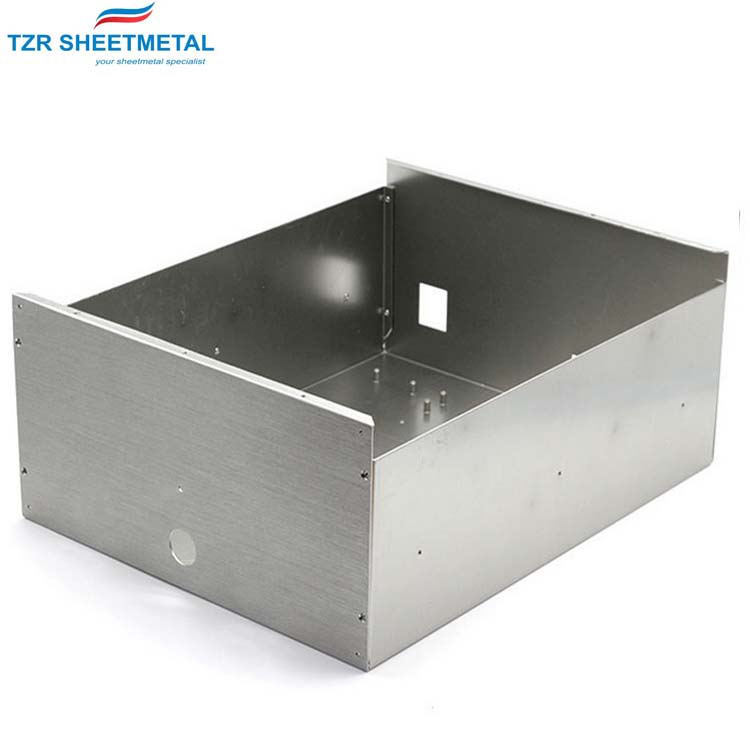

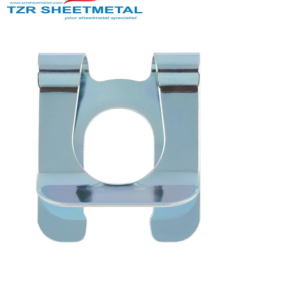

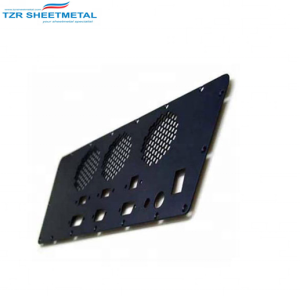

Product Pictures