Metal fabrication of a rolling transporter of hot meals for the aviation industry

Review

Description

Project Description | Rolling transporter of hot meals used in airplanes |

Capabilities Applied/Processes | Metal fabrication |

Equipment uesd to manufacture part | N/C Punch, Laser,Press Brake,Deburr Machine,Hardware Inserter,Rivet Gun |

Overall Part Dimensions | 22"×35"×36" |

Tightest Tolerances | ±.005” |

Material Uesd | .036 SST 304 #4 |

Material Finish | SST #4 |

Industry for use | Aviation |

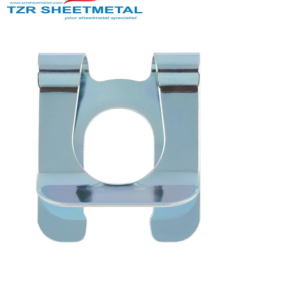

Product pictures

Description

At TZR Sheetmetal Co,ltdour facility houses state-of-the-art machinery that enabled us to efficientlymanufacture the aircraft galley service equipment shown here. In this project,we worked in close partnership with the client to create a rigidly constructedunit with high strength properties that met the requirements for both safe foodhandling and FAA regulations. Our manufacturing team evaluated every aspect ofdesign, materials, and process to ensure this product met very robust qualitystandards for both structure and appearance.

Featuringfinished dimensions of 22” in width x 35” in depth x 36” in height, thisrolling transporter is constructed mainly from .036” thick 304 stainless steelsheet with a brushed finish. In addition to being structurally strong, thismaterial is very compatible with food handling and tolerates a wide range ofatmospheric environments. We leveraged many of our fabrication capabilities,including precision numerically controlled punching, laser cutting, and bendingto produce parts with tight dimensional tolerances of ±.005”. Assembly involvedhardware insertion and riveting, which has the resilience to maintainstructural integrity in a trolley that has to withstand jarring movement andvibration from aircraft ascent, descent, or turbulence.