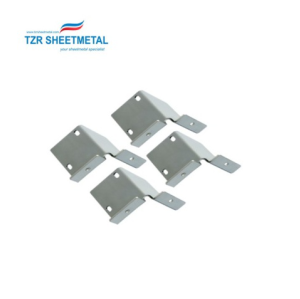

Precision Stainless Steel Bending Stamping Part Sheet Metal Fabrication aluminum parts

Review

Description

Feature:

Material:Steel, Stainless steel, Aluminium, Brass, etc.

Specification:As your drawing

Processing:Laser cutting, bending, punching, welding, stamping, riveting, etc.

Surface treatment:Polishing, galvanizing, powder coating, anodizing, electroplating, brushing, silk screen, etc.

Drawing format:CAD, solidworks, PDF, pictures

Service Type:OEM&ODM

Certificate:ISO9001, SGS, TUV

Factory area:6000 square meters

Introduction:

In general, the basic equipment of the stamping parts factory includes Shear Machine, CNC Punching Machine/Laser, Plasma, Waterjet Cutting Machine/Combination Machine, Bending Machine and various auxiliary equipment such as uncoiler, leveling machine, deburring machine, spot welding machine, etc.

Usually, the most important three steps of the metal stamping die factory are cutting, punching/cutting and folding.

Stamping parts are sometimes used as the gold plate. The word comes from the English platemetal. Generally, some metal sheets are plastically deformed by hand or die to form the desired shape and size, and can be further welded or a small amount of machining. The formation of more complex parts, such as the chimneys commonly used in the home, the iron stove, and the car shell are all sheet metal parts.

Application:

Metal Stampings uses different types of copper for your stamping project. Our metal and alloy specialists can help you select the type of copper that is best for your application, and copper may be alloyed with other metals to improve strength and long-term durability. Common copper uses include:

· Architectural features

· Solar heat collectors

· Air conditioning components

· Electrical applications

· Medical devices

· Transformers, motors & cables

· Plumbing & roofing

· Hygienic vessels

Function:

. Conductivity & heat resistance: Second only to silver, copper possesses superior thermal conductivity that makes it a staple for electrical, HVAC and gas tubing applications.

. Finish: A beautiful “colored” metal, copper is often selected for architectural, design hardware and consumer goods applications.

. Durability & corrosion resistance: Copper is non-reactive, and does not become brittle in sunlight or cold temperatures. It can also be alloyed with other metals to improve corrosion resistance in adverse environmental conditions.

. Malleability and ductility: Copper’s high ductility and malleability after hardening makes it ideal for wiring, tubing, and other industrial purposes.

. Sanitary: Copper is a naturally hygienic metal with antimicrobial properties, making it useful for the food & beverage industry.

. Sustainability: Copper is highly recyclable without degradation or quality loss, so it is an attractive green option.