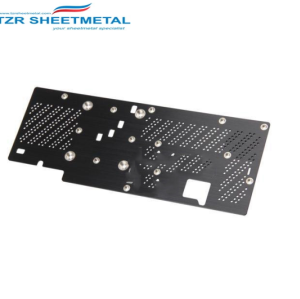

OEM customized aluminum stamping parts of high precision sheet metal processing and anodic treatment

Review

Description

Product description

Item name | OEM customized aluminum manufacturing pressing components price high precision sheet metal fabrication with anodizing finish |

Machining Equipment | Laser Cutting Machine/CNC Shearing Machine/Flat Bed Spot-welder/Die Grinder/Steel Processing Machine/Double Servo Turret-type Punch Press/Banding Machine/Steel Processing Machine/etc. |

Material | Carbon steel/Mild steel/Cold roll steel/Hot roll steel/Zinc plate/Stainless steel/Aluminum/SECC/SGCC/SPCC/SPHC/Other metal |

Surface Treatment | Blacking,polishing,anodize,chrome,plating,zinc plating,nickel plating,tinting |

Design | OEM/ODM |

Sample lead time | 6-10 days |

Mass order | 15-25 days, according to the quantity |

Payment | T/T, Western Union, Paypal |

Advantages of sheet metal fabrication

1.1.Relationship of a high strength.

2.2.Thinness and low in weight can be transported easily.

3.3.Resistance to sun, corrosion and also moisture. With the different types of weather conditions this sheet metal fabrication seems to work perfect.

4.4.Sheet metal fabrication ensure durability as they are able to withstand any sort of pressure while at the same time, these are malleable.

5.5.Malleability as this sheet metal fabrication can be formed into any shape which is desired. This can provide unlimited amount of designs for structures and buildings.

6.6.The plans and visions of engineers and architects can be materialized with the technology of sheet metal fabrication.

Product pictures

Packing & Shipping

Our customer